Some long-haul drivers are dealing with a problem with the hours of service (HOS) that makes them feel they have a problematic leak rather than being in conflict with the rules. You start your routine day with a complete clock, but as the day goes between loading delays, traffic, inspections, and poor planning, your 11/14 hours disappear. You are not breaking the rules — rather, you are not controlling them.

In long-distance trucking, processing the HOS procedure is not so much about getting the most miles out of the clock. It is rather about perceiving how HOS works under real OTR conditions and how to keep your driving limit protected from being diminished with unnecessary on-duty time before it actually is.

In long-haul trucking, time management matters as much as mileage, because hours lost early in the shift rarely return later.

In this piece of writing, we will try to explain how professional truck drivers can operate under the 11-hour driving and 14-hour duty limits by their own choice without troubles, violations, or lost productivity.

The Main Reason Why Long-Haul Drivers Are Losing Hours Without Realizing It

Most of the HOS problems are not produced by the intentional violations, rather, they do come from the misunderstanding of how the on-duty window behaves over a long-haul day.

In the operation of OTR, your clock isn’t just tracking driving—as it also records everything related to a commercial vehicle operating like fueling, inspections, dock waiting, traffic jams, and even slow yard moves which can quietly take your time.

In OTR trucking, the clock often runs faster than expected due to factors drivers cannot fully control.

After the 14-hour duty timer begins, it will not stop for you. Most drivers who fall into that trap believe that they are saving time by stopping. The truth is it will not work.

Understanding the 11/14 Structure in Simple Terms

The HOS framework for long-haul drivers is built up around two fixed limit structures:

11-hour driving limit — is the longest period of time that you are able to drive

14-hour duty window — the entire working period of a day

Besides this, in fact, you may operate your vehicle more but once the 14-hour window closes, the driving hours allowed would be none.

The key point of this setting is the preempt unloading of driver fatigue rather than infringing the productivity of the driver. Of course, if you do not plan the load earlier, the clock will stay your opponent.

Core 11/14 hour structure

| HOS element | What it controls |

| 11-hour limit | Maximum driving time |

| 14-hour window | Total length of workday |

| On-duty time | All work-related activity |

| Off-duty time | Recovery and clock reset |

The Chief Enemy: Uncontrolled On-Duty Time

On-duty time has been the main source of schedule loss for long-haul drivers. Anything that is not sleeper berth or off-duty time clearly counts towards the 14-hour timer.

Common time drains may include:

- long loading and unloading times

- slow customer check-ins

- fuel stops that weren’t planned

- unnecessary yard moves

- inspections that were done at the wrong time

Poor control of shift duration often leads to drivers running out of usable hours before reaching safe parking.

Typical on-duty time losses

| Activity | Hidden impact |

| Dock waiting | Eats driving window |

| Yard moves | Triggers duty status |

| Poor fueling timing | Splits productive hours |

| Early inspections | Starts clock too soon |

Starting the Clock Too Early

Another significant mistake in long-haul operations is to start the day too early. Many drivers come on duty before they really need to do that, thus inadvertently triggering the on-duty window ahead of time.

Once the window starts running, it does not stop—even if you are not going anywhere.

The HOS procedure for professionals begins with putting off on-duty status until the vehicle is moved or other work is required. This very simple habit can protect you to the hours at the end of the day.

Pre-Trip Inspections Without Burning Time

Inspections are a must, but one key is that they do not have to eat your clock. The question of time here is the heart of it.

By performing inspections after fueling, while waiting for dispatch instructions, or during natural pauses, you will save the most precious part of your day which is driving time in the 14-hour window. Good driver tips focus on stacking tasks, not separating them.

Why Waiting Time Is the Silent Killer of Hours

The waiting game will always exist in long-haul and is out of your hands. But your commitment to log it right can change your game.

Waiting while being blocked at a dock, parked with no work required, or unable to move due to facility control may qualify as off-duty or sleeper berth in certain situations depending on regulations and company policy.

Misclassifying your waiting-time as on-duty is one of the quickest ways to eat up your available hours without moving the truck at all. Avoiding violations starts with understanding where time is lost, not where rules are broken.

Sleeper Berth: More Than Just Sleeping

Sleeper berth is often underestimated. It is not only a place to sleep overnight but also it is a tool for the long-haul driver to control HOS management.

These berths can lower fatigue, manage split rest, extend driving windows, and contribute hours to being off consecutively. The sleeper berth lets a driver intentionally redefine and not just passively adjust their day. In long-haul operations, this strategically becomes crucial especially under the conditions of unpredictable dock schedules, prolonged waits, adaptations in the delivery schedule, etc. The right way to use the sleeper gives the drivers a chance to stop the build-up of fatigue without having to give away any driving time in the future.

However, the sleeper berth concern practically requires consistency and learning. Unplanned sleep or irrelevant sleep times often create confusion during the inspection process and may raise questions about log accuracy. Considering the sleeper berth as a strategic rest tool instead of the last resort makes it easier to understand, keep the rules, and recover physically over the shifts.

Mandatory Breaks and Strategic Timing

A mandatory break is not a problem at all. Setting a poor time is.

The goal is not to rush but to maximize driving within legal limits by protecting the most productive hours of the day.Only if they are the reason of stopping the team to progress their task Mandatory breaks are only disruptive. A break taken far too early in the shift can usually be the reason for a fragmented driving window and the drivers having to stop again later when they would prefer to keep the flow. Unplanned breaks can also cause problems, which might lead to driving in congested periods, thus increasing stress and decreasing efficiency.

The advanced long-distance drivers see that the mandatory breaks are not interruptions; rather, they are like the anchors. Connecting them with other activities like refueling, eating, or relaxing during natural slow traffic periods makes a legal requirement just a neutral event and not an opportunity lost. Insightful timing keeps the day in balance and maintains the energy for the last run of driving.

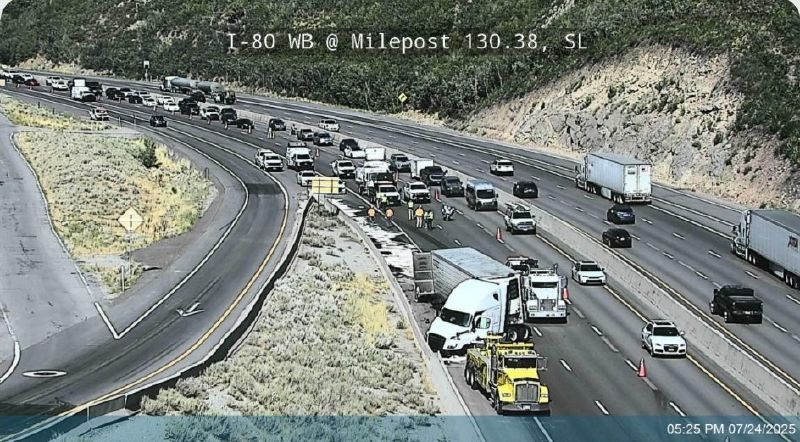

DOT Regulations Are Predictable – Your Day Isn’t

DOT regulations are structured to limit fatigue accumulation rather than restrict earning potential. Check Link

Traffic, customers, weather, and dispatch remain unpredictable, which is why buffer planning is essential.Regulations provide a stable framework, but the reality of long-haul driving rarely follows a straight line. Delays, weather shifts, and facility bottlenecks can quickly erode even the best-laid plans. Drivers who rely on perfect conditions often find themselves pressed against the limits of their clocks.

Building buffer time into each shift allows drivers to absorb disruptions without panic. This approach reduces last-minute decisions, protects compliance, and supports safer driving behavior. The most reliable long-haul schedules are not the tightest ones, but those designed with flexibility in mind.

Common Long-Haul HOS Mistakes

Most violations are a result of behaviors, not a single action.

Frequent HOS mistakes and outcomes

| Mistake | Result |

| Starting duty too early | Shortened driving window |

| Logging everything on-duty | Lost usable hours |

| Misusing sleeper berth | Inspection questions |

| Ignoring delays | Clock exhaustion |

Final Thoughts: Control the Clock, Don’t Fight It

The 11-hour driving and 14-hour duty limits are not traps, but margins. The problem is not the rules; it is about small unmanaged tasks taking away the most valuable thing — time.

With a structured HOS procedure, professional drivers can control their day, stay compliant, and avoid the feeling that their hours are being devoured.

FAQ

1. What causes long-haul drivers to lose their 11/14 hours so quickly?

The majority of the hours are lost not during driving, but during uncontrolled on-duty time. Clock starts that are too early, extended dock waits, poorly timed inspections, and unnecessary yard moves are the destructive factors that ultimately drain the 14-hour window before drivers realize it. After that time window disappears, unused driving hours become irrelevant.

2. Is it beneficial to have the initial shift early to “get ahead” of the day?

Not always. Getting on-duty too early often shortens the usable driving window later in the day. In long-haul trucking, delaying the start of on-duty status until work is actually required helps preserve hours when traffic, weather, or customer delays appear.

3. Can sleeper berth time actually help extend my driving day?

Sleeper berth time does not stretch the 14-hour window, but it can manage fatigue and support split rest strategies. Used with purpose, it allows drivers to rest without turning short pauses into wasted on-duty time. When combined correctly with consecutive hours off, it supports recovery while keeping logs clean and inspection-ready. Random sleeper entries, however, often create confusion during inspections.

4. Why do mandatory breaks feel like lost time?

Mandatory breaks feel costly only when they interrupt momentum. Poorly timed breaks—taken too early or during low-demand periods — fragment the day. When aligned with fueling, meals, or congestion, they shift from disruptive to neutral.

5. How can I get more driving done without risking violations?

Maximizing driving means protecting the most productive hours of the shift. This includes stacking tasks, planning stops ahead of congestion, managing on-duty time carefully, and leaving buffer room for delays. It is about control, not speed.

6. Are DOT local regulations framed to curb driver earnings?

DOT regulations are designed to reduce fatigue and improve safety, not to limit earnings. Drivers who understand how to work within these constraints often achieve more consistent results than those who constantly push the edge of the clock.

7. What is the most common HOS error among long-haul drivers?

Using on-duty status incorrectly is the most common mistake. Logging all time as on-duty when some of it could qualify as off-duty or sleeper berth subtly reduces shift duration and increases stress near the end of the day.

No responses yet