Introduction

A roadside inspection for a rookie truck driver can be seen as an unpredicted exam instead of a usual safety check. One is driving on the highway, concerned about the traffic, receiving a warning about a possible delay in delivery, when suddenly, the police turned on their lights. Basically, whats going on at the moment is that instead of the regular lesson in the CDL course you are being tested instead about the lighting, brakes, documents, logs, tires, and even your own behavior.

A roadside inspection is simply the Department of Transportation carrying out an inspection on your truck. It aims to look at any vehicle technical problems, shortfall in compliance, and safety concerns that may lead to further issues such as accidents, breakdowns, or monetary fines. The reality, however, is that overtime and practical lessons indicate that the same statistical trend hold true year after year even among inexperienced drivers; rookie mistakes continue to dominate inspection reports.

These kind of errors are not usually eye-catching. They just tend to be small things forgotten here and there, things that have been done incompletely, or misunderstandings as to what is required, or what inspectors look for. Nevertheless, even if those “minor” issues usually do not lead to fines, they might still result in truck downtime, repair costs, and the company losing the CSA profile.

This article shows ten errors, explains the reasons why drivers commit those mistakes, and offers tips on how to overcome them — not by learning the regulations by heart, but by incorporating the necessary practices of being inspection-ready into the day-to-day driving.

Top 7 Rookie Trucking Mistakes that COST YOU BIG on the Road

Reasons Why Roadside Inspection Are Difficult for Rookie Drivers

Drivers with experience tend not to be plagued by the same vehicle defects as new drivers do, they simply manage them better. Problems that new drivers have include:

They either forget to check some things off the pre-trip inspection list or they don;t do proper pre-trip inspections at all.

They do not have a proper understanding of hours of service (HOS) details. They lack proper maintenance records. They even have problems recognizing early-stage damages on a vehicle.

A roadside inspection is not just a single failure; it’s a series of patterns. When multiple minor faults appear it can trigger the risk which can be reflected in the inspector’s mind, even if every issue is not that critical on its own.

Items Inspectors Focus on First

| Inspection Area | Reason for Importance | Common Difficulties of Runts |

| Driver documents | Word of legality | Absence of documents or outdated paperwork |

| Lighting & electrical | Visibility and signaling | Burnt bulbs, loose wiring |

| Tires & wheels | Road contact and load safety | Uneven wear, loose lug nuts |

| Brake system | Stopping power | Out-of-adjustment components |

| HOS & logs | Fatigue prevention | Incorrect entries |

| Cargo securement | Public safety | Inadequate straps or chains |

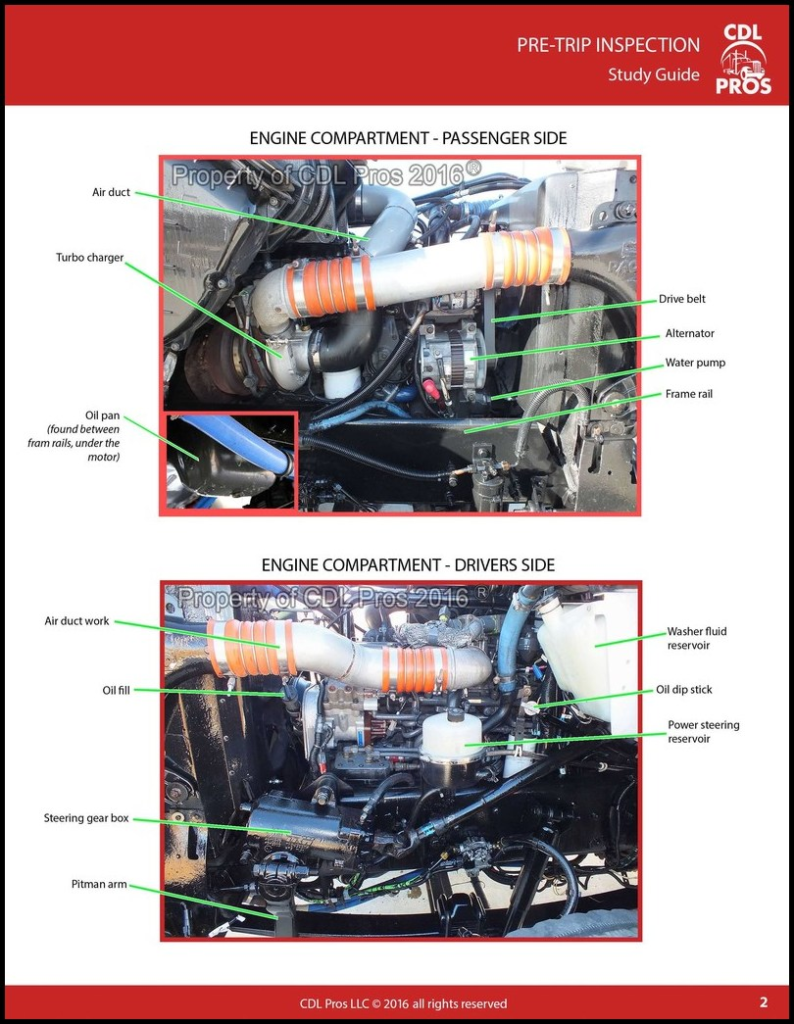

Mistake #1: Regarding the Pre-Trip Inspection as a Formality

Most new drivers see the pre-trip inspection as a formality and rush through this fundamental task instead of it being a tool for safety. However inspectors that have good experience pay close attention to the proper pre-trip check as a visible sign of whether the driver even understands what actually their truck is.

Oblivion of the steps like skipping them, or a so-called memory-based inspection leads to unsupported vehicle defects like the following ones:

- Braking system air leaks

- Loose hoses or fittings

- Worn tires that look “acceptable” at a first glance

Decrease the tempo of the operation. Touch wires and hoses. Work on a consistent checklist that makes you touch crucial components to confirm their condition rather than just think of them being okay.

Mistake #2: Incomplete or Disorganized Driver Documentation

During a DOT inspection, paperwork is not secondary — it’s foundational. Driver documentation issues are one of the fastest ways for a routine check to escalate.

7 rookie truck driver mistakes and how you can avoid them

Common rookie mistakes include:

- Carrying expired medical cards

- Missing vehicle registration copies

- Incomplete inspection reports

Even if the truck itself is in good shape, documentation gaps signal compliance problems.

Keep all required documents in one clearly organized folder. Review it weekly, not just when stopped. Paperwork should be inspection-ready at all times, not “almost ready.”

Mistake #3: Not Knowing the Electrical and Lighting Issues

Light issues are the most common culprits of roadside inspection and the most familiar problems for drivers to deal with. Less experienced drivers depend too much on the idea that if nothing is obviously broken, then the lights are all working.

In reality, inspectors often find:

- Broken log lights

- Blinking brake lights

- Wires moved by vibration or moisture

These are specific electrical problems that will show between scheduled services.Most lighting issues develop gradually, which is why they are frequently overlooked until they are identified during a roadside inspection.

Check all lights during every pre-trip and post-trip inspection. Walk around the truck at night when possible — darkness exposes lighting failures that daylight hides.

Mistake #4: Missing Initial Tire Defects

Tires tend to become defective over time, not all at once. New drivers often search for serious damage at the same time overlooking early signs of tire defects such as:

- Uneven tread wear

- Sidewall bulges

- Embedded debris

They may not lead to an immediate breakage of the tire but still they are a matter of inspection.

Use a monitor, not a guess. Check with a tread depth gauge and a pressure gauge on a regular basis. Tires are the most obvious elements that inspectors observe to assess driver knowledge.

Mistake #5: Not Wheel Check Defects Until They Are Obvious

Wheel defects, especially loose or damaged lug nuts, are very much connected with tire issues. New drivers might be slow to detect such marks as rust trails or shiny spots from movement.

Inspectors can.

During inspections, look for symmetry. Missing lug nuts, cracks, or irregular patterns should stand out immediately. Checking the wheels should be both visual and tactile.

Mistake #6: Poor Understanding of Brake Functionality

The brake system is a vital part of the truck and most drivers will examine both the airbrake and the electrical system during a roadside inspection. Most rookie drivers simply think that “brakes are handled by maintenance.”

However, inspectors look for:

- Slack Adjustor travel

- Amount of air pressure build-up

- Audible leaks

For instance, a lack of knowledge about how brakes work when they are functioning well prevents the driver from detecting the issue at the recommended time.

Find out how brakes sound and feel when they are operating as they should. Any deviation should send you to the further inspection before hitting the road.

Mistake #7: Cargo Securement Made Out of Assumptions

Many newbies think that cargo securement is only crucial for flatbeds; however, it is actually applicable to all types of freights and goods.

Some common mistakes are:

- Insufficient load bars

- Worn straps

- Improper weight distribution

Inspectors are not interested in the fact that the load has not moved yet. Their major concern is the possibility of the load moving.

Tie down the cargo considering the worst conditions, not the average ones. Think sudden braking and evasive maneuvers which the inspectors are assessing against.

Mistake #8: Hours of Service Errors That Look Minor

Minutes of service (HOS) mistakes are mostly due to a misunderstanding of the rules, and not because people are purposely trying to be noncompliant. Rookies’ errors are:

- Changing the duty status in an incorrect way

- Missed Annotations

- Log-editing inconsistencies

Little mistakes like that in an outbound inspection could be one of the symptoms of fatigue risk.

Be consistent in reviewing your logs or daily schedule rather than weekly ones. Understand the real importance behind each entry, not just how to do them. Always be accurate rather than fast.

Mistake #9: Skipping the MC Inspection

Many drivers think of the MC inspection as a relatively optional check, but the inspectors don’t buy this.

Not doing it leads to:

- Unreported vehicle defects

- Accumulated maintenance issues

- Poor compliance records

The performance above usually marks red flag during the inspection.

Make use of post-trip inspections to catch issues early. It works both ways as it protects you and the equipment by showing due diligence and consistency.

Mistake #10: Not Understanding How Behavior Affects the Results of the Inspections

Though inspections are devoid of being subjective, yet the way a driver behaves is still a determining factor. New drivers can be:

- Nervous

- Defensives

- Unprepared

These factors do not lead to violations, but they can possibly affect how deep the inspection goes.

Stay calm, answer directly, do not over-explain. The confidence comes from the preparation not from the attitude.

Rookie Mistakes and Their Consequences

| Mistake Category | Immediate Risk | Long-Term Impact |

| Documentation errors | Inspection delay | CSA score damage |

| Lighting or electrical issues | Out-of-service orders | Repeat violations |

| Tire and wheel defects | Roadside breakdown | Expensive truck repair |

| Brake system issues | Safety shutdown | Increased violation risks |

| HOS mistakes | Log violations | Compliance audits |

Important Habits That Can Reduce Inspection Failures

Having the right habits is more important than remembering a few rules.This mindset helps drivers focus on avoiding pitfalls that often lead to repeated inspection failures and long-term compliance risks.

Inspection-Ready Driver Checklist

Consistently follow an inspection checklist

Carry out both pre-trip and post-trip inspections every day

Make maintenance records accessible

Review HOS entries each shift

Maintenance Awareness Essentials

Report defects immediately

Understand the basics of vehicle systems

Monitor repeated issues

End thoughts: Transforming Inspections into Non-Events

A roadside inspection can be a smooth process and most of the time, experienced drivers are not bothered by it. The demarcation is not about sheer luck or being let off lightly. It;s about the right preparation, being aware, and consistency throughout the way.

The majority of new driver mistakes arise from the driver rushing, assuming, and misunderstanding what actual compliance looks like in practice. However, If a rookie driver put his heart, mind, and energy to correcting these ten mistakes, he can significantly lower the risks of violation, learn to drive without a fear of anything, and finally, build confidence behind the wheel.

Inspections will always be a part of trucking, while failing them is not.

FAQ: Roadside Inspections and Rookie Drivers

By skipping the pitfalls, one not only prepares for the roadside inspection long before the actual date but also adopts this practice throughout the company. Over time, drivers have developed the habit of adhering to the right equipment checklists, verifying the documents, and keeping track of even the slightest changes in truck configurations, which has resulted in their overcoming almost all the inspection-related problems. Consequently, compliance is no longer an end-of-the-month activity but a part of the normal working day.

What causes inspector treatment of driver documentation as red flags?

The documents submitted by the driver are basically an overview of the compliance level of that driver in particular. If the documents are missing, expired, or poorly organized, they can reflect a driver’s attitude of neglect, even when the vehicle itself is in good condition. Issues with the paperwork are often seen by the inspectors as the signs of other possible activity risks.

Are there significant effects of the repeated new driver errors on the inspections in the long run?

Yes. The pattern of repeated new driver errors that arises is one of the main reasons for most compliance issues. While some of the mistakes may seem insignificant at times, their cumulative effect is the cause of increased inspection depths, harsher violation risks, and often the need for even more thorough future roadside checks. The keys to breaking this cycle are consistency and correction.

No responses yet